Why

PU Flooring?

- Resistance to solvents and alkalis. As with epoxy, certain chemical reactions simply have less impact on polyurethane products than epoxy ones. For areas in contact with oils and solvents, polyurethane is the best option.

- Speed of curing. Polyurethane will cure faster than epoxy in most situations. In time-sensitive operations or where the resin is needed for a mission-critical application, this is one of the advantages polyurethanes bring.

- Resistance to scratching. The polyurethane finish is less scratchable than the epoxy finish.

- Life cycle costs. An important advantage of polyurethane flooring systems is the possibility to renew the topcoat without complete removal of the flooring system.

Process of

Applications

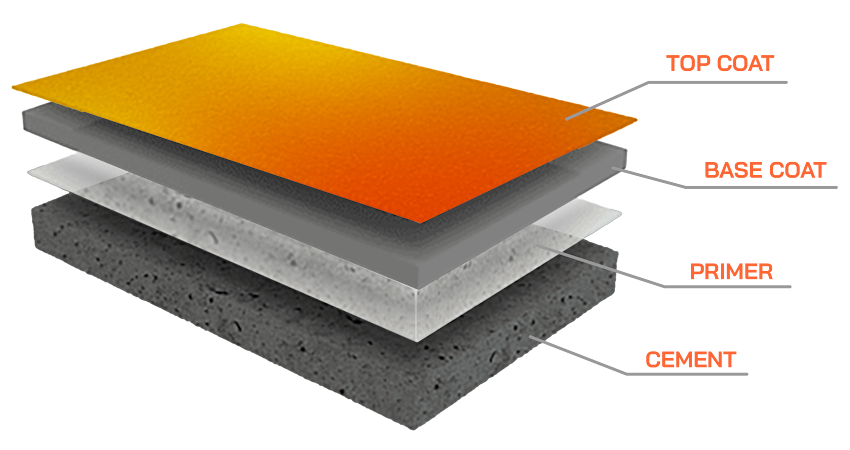

- Mop your concrete or hardwood floor with mineral spirits. Mineral spirits are clear liquid solvents that are used as paint thinners. It will not only clean but also make the surface smoother and prepared for PU coating paint.

- Wait for the mineral spirits to evaporate.

- Stir the polyurethane in the can with a wooden paddle until it becomes clear.

- Pour some PU on the floor in a corner. Paint in a straightforward motion and use a lamb’s wool applicator to do so. Keep doing this until the floor is covered in your first layer of PU coating.

- Wait for the first layer to air-dry for an hour before painting over the second layer. Keep doing this until you have 4 layers.