Why

EPOXY FLOORING?

- Epoxy floors are resistant to a large number of chemicals such as solvents and acids.

- The floors are decorative. Epoxy floors are available in many different colors and designs. It is possible to create a concrete look or to sprinkle the floor with flakes.

- Because of the fast application there is only minimal work interruption.

- Epoxy floors are very easy to maintain.

- This makes epoxy floors suitable for heavy use and mechanical loads, such as forklift traffic in warehouses, workshops and production areas.

Process of

Applications

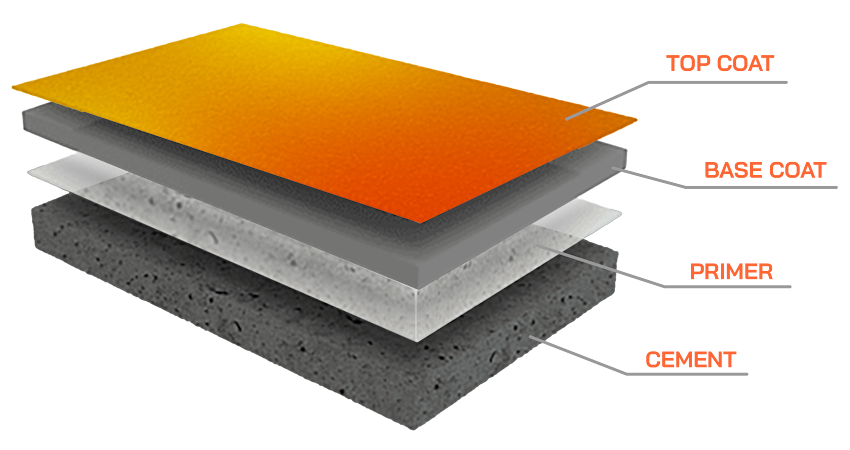

- Preparing the surface before applying the epoxy-Preparation of the substrate is necessary in order to ensure adhesion between the epoxy product and the substrate. The most common methods for surface preparation are Grinding with a diamond grinding and Sanding.

- Sweeping and cleaning of the floor. You must now vacuum the floor. You cannot have any dust or residue before applying any type of epoxy or primer.

- Prime the floor with our PRIMER. IF the product gets very quickly absorbed by the substrate. This is very common with dusty and soft cement-based floors apply a second coat of primer.

- Apply your coat of our BASE COAT. The level of base coat depends on your requirement and wait for it to dry for 24hrs.

- Apply the final coat of TOP COAT and let it try.